Uhlangothi olulodwa lwe-Aluminium Base Circuit Board LED strip PCB for Lighting Conversion

Ulwazi lokukhiqiza

| Imodeli No. | I-PCB-A11 |

| Iphakethe lezokuthutha | Ukupakisha Vacuum |

| Isitifiketi | UL, ISO9001&ISO14001,RoHS |

| Izincazelo | IPC Ikilasi 2 |

| Ubuncane beSikhala/Ulayini | 0.075mm/3mil |

| Ikhodi ye-HS | 8534009000 |

| Umsuka | Kwenziwe eshayina |

| Amandla Okukhiqiza | 720,000 M2/Ngonyaka |

Incazelo Yomkhiqizo

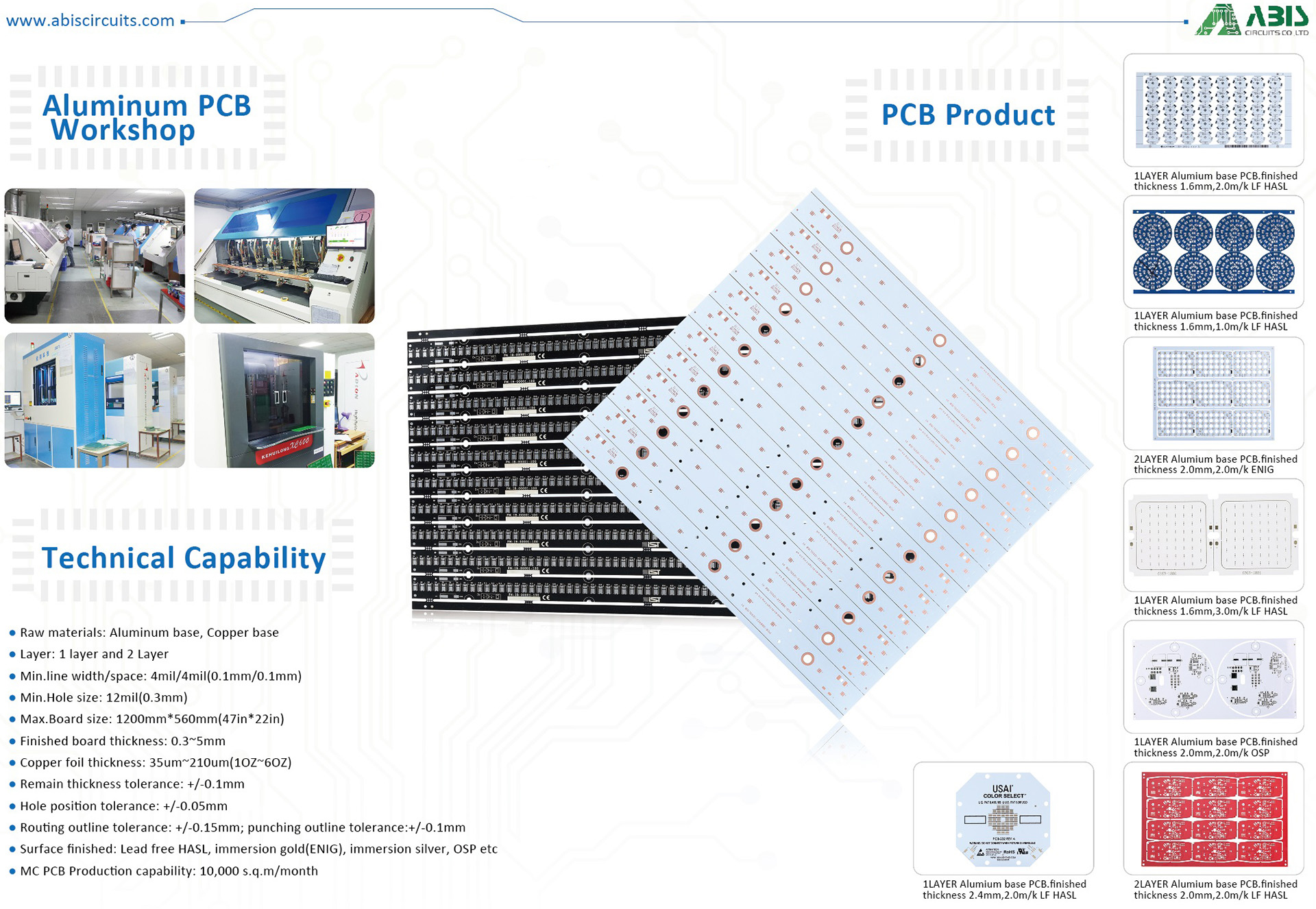

I-ABIS ibikhiqiza ama-PCB e-aluminium iminyaka engaphezu kwe-10.Isici sethu esigcwele samabhodi esekethe e-aluminium okwenza amakhono kanye Nokuhlola Kwamahhala kwe-DFM kukuvumela ukuthi uthole ama-PCB e-aluminium ekhwalithi ephezulu enziwe ngaphakathi kwesabelomali.

Isingeniso se-Aluminium PCBs

Incazelo

Isisekelo se-Aluminium yi-CCL, uhlobo lwezinto eziyisisekelo zama-PCB.Kuyinto eyinhlanganisela eyenziwe nge-foil yethusi, ungqimba lwe-dielectric, ungqimba oluyisisekelo lwe-aluminium kanye nolwelwesi oluyisisekelo lwe-aluminium olunokukhishwa okuhle kokushisa.Kusetshenziswa ungqimba oluncane kakhulu lwe-dielectric conductive thermally kodwa insulating kagesi, e-laminated phakathi kwesisekelo sensimbi nongqimba lwethusi.Isisekelo sensimbi siklanyelwe ukudonsa ukushisa kude nesekhethi ngokusebenzisa i-dielectric encane.

Kungani i-Aluminium isetshenziswa ekukhanyeni kwe-LED?

Ukukhanya okunamandla okukhiqizwa ama-LED kudala amazinga aphezulu okushisa, i-aluminium eqondisa kude nezingxenye.I-PCB ye-aluminium inweba isikhathi sempilo yedivayisi ye-LED futhi inikeza ukuzinza okwengeziwe.

I-aluminium empeleni ingadlulisa ukushisa kude nezingxenye ezibalulekile, ngaleyo ndlela inciphise umthelela oyingozi ongaba nawo ebhodini lesekethe.

Ezobuchwepheshe nekhono

| Into | I-Speci. |

| Izendlalelo | 1~2 |

| Ukuqina Kwebhodi Elivamile Lokuqeda | 0.3-5mm |

| Okubalulekile | Isisekelo se-Aluminium, isisekelo sethusi |

| Max Panel Usayizi | 1200mm*560mm(47in*22in) |

| Usayizi we-Min Hole | 12mil(0.3mm) |

| Ububanzi/Isikhala Somugqa Omncane | 3mil(0.075mm) |

| Ukuqina kwe-Copper Foil | 35μm-210μm(1oz-6oz) |

| Ukuqina Kwethusi Okujwayelekile | 18μm, 35μm, 70μm, 105μm. |

| Hlala Ukuqina Ukubekezela | +/-0.1mm |

| Ukubekezelela Kohlaka Lomzila | +/-0.15mm |

| Ukubekezelela Kohlaka Oluhlabayo | +/-0.1mm |

| Uhlobo Lwemaski Solder | I-LPI(isithombe esiwuketshezi) |

| Okuncane.I-Solder Mask Clearance | 0.05mm |

| I-Plug Hole Diameter | 0.25mm--0.60mm |

| Ukubekezelelana Kokulawulwa Kwe-Impedans | +/-10% |

| Ukuqedwa kobuso | I-HASL yamahhala eholayo, igolide lokucwiliswa (ENIG), i-sliver yokucwiliswa, i-OSP, njll |

| I-Solder Mask | Ngokwezifiso |

| Isikrini sikasilika | Ngokwezifiso |

| I-MC PCB Amandla Okukhiqiza | 10,000 sqm/ngenyanga |

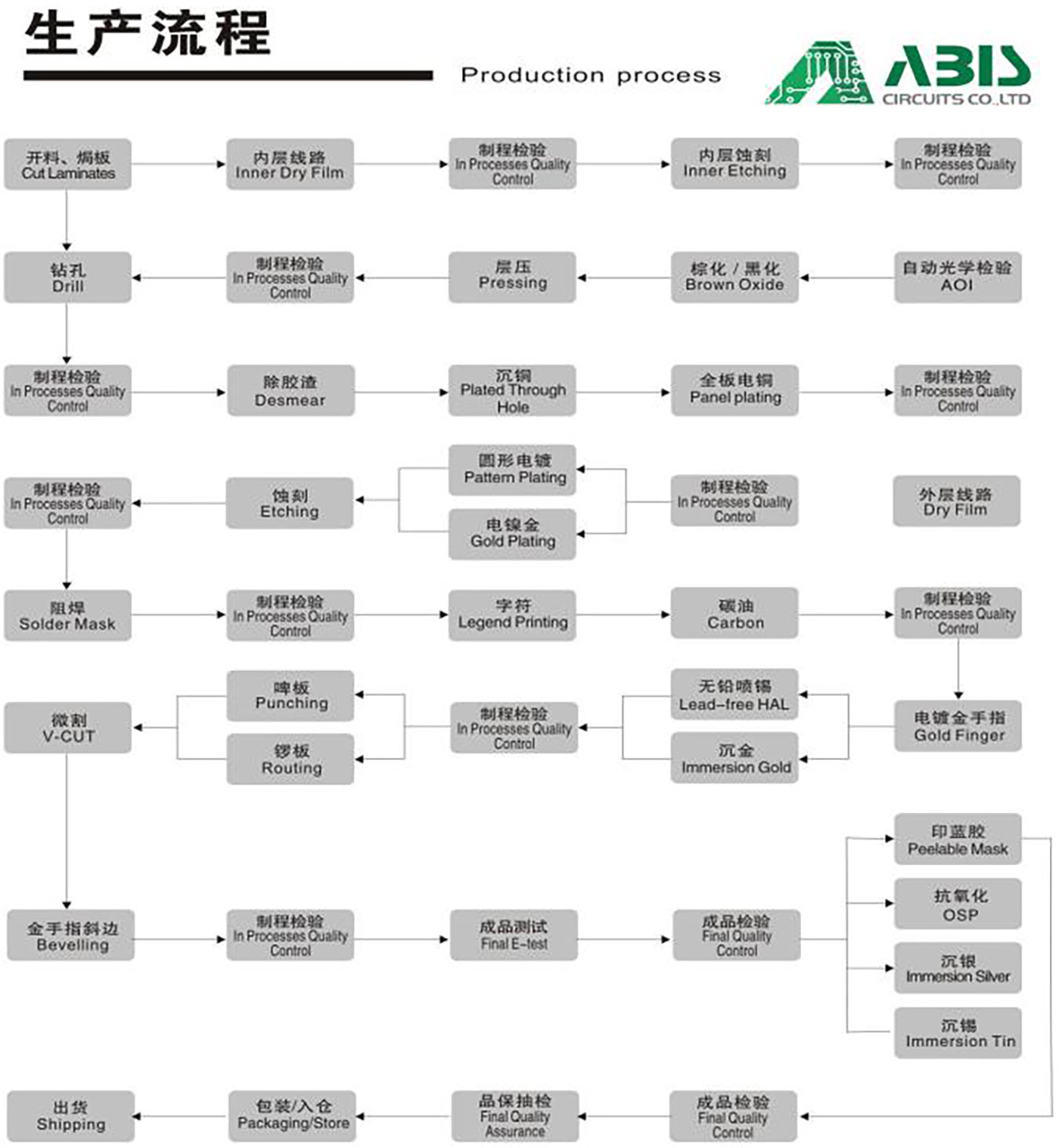

Inqubo Yokukhiqiza ye-PCB

Isikhathi sokuhola se-Q/T

Njengokujwayelekile kwamanje, senza kakhulu i-PCB eyodwa ye-aluminium, kuyilapho kunzima kakhulu ukwenza i-PCB ye-aluminium enezinhlangothi ezimbili.

| Ivolumu Yeqoqo Encane ≤1 imitha-skwele | Izinsuku Zokusebenza | Ukukhiqiza Okuningi >1 imitha sq | Izinsuku Zokusebenza |

| Uhlangothi Olulodwa | Izinsuku ezingu-3-4 | Uhlangothi Olulodwa | 2-4 amasonto |

| Izinhlangothi Ezimbili | Izinsuku ezingu-6-7 | Izinhlangothi Ezimbili | 2.5-5 amasonto |

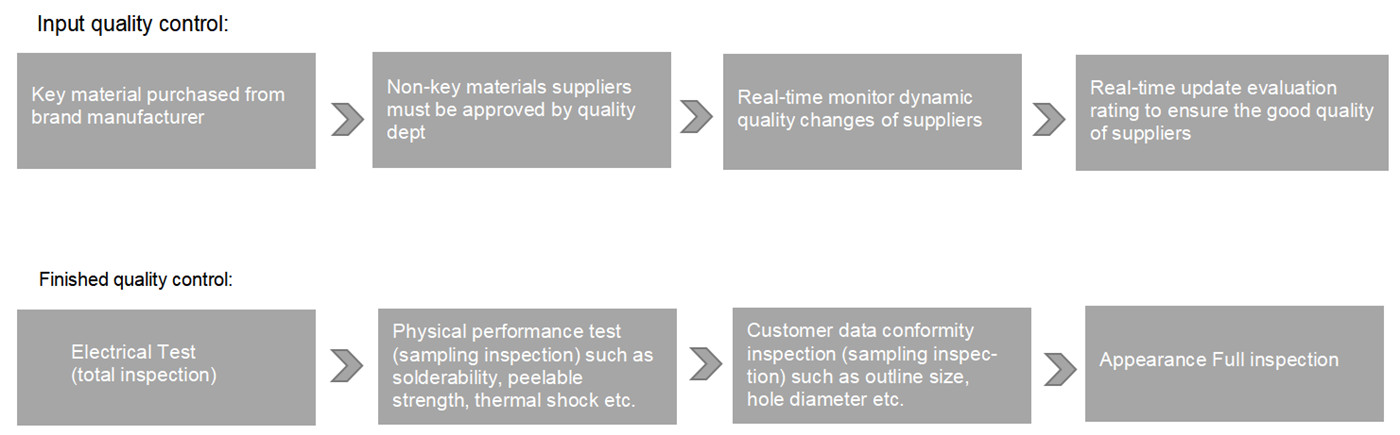

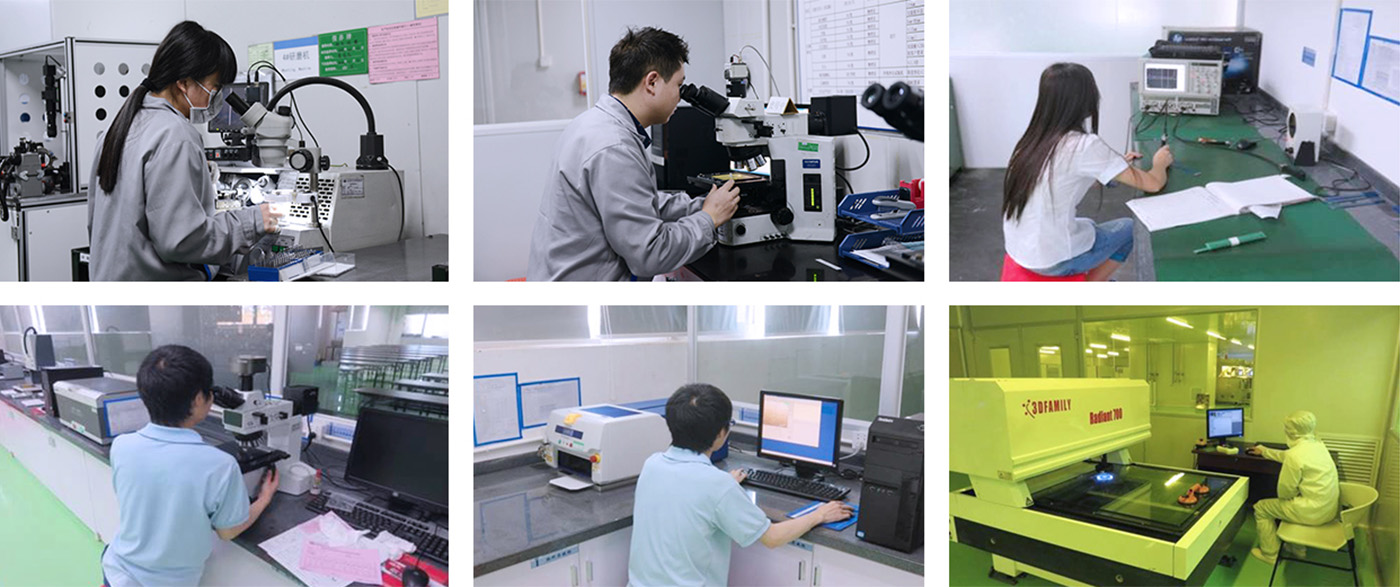

Ikhwalithi yokulawula

Izinga lokuphasa lezinto ezingenayo ezingaphezu kuka-99.9%, inani lamazinga okunqatshwa kwenqwaba angaphansi kuka-0.01%.

Izikhungo eziqinisekisiwe ze-ABIS zilawula zonke izinqubo ezibalulekile ukuze kuqedwe zonke izinkinga ezingase zibe khona ngaphambi kokukhiqiza.

I-ABIS isebenzisa isofthiwe ethuthukisiwe ukwenza ukuhlaziya okubanzi kwe-DFM kudatha engenayo, futhi isebenzisa ikhwalithi ethuthukisiwe

lawula amasistimu kuyo yonke inqubo yokukhiqiza.

I-ABIS yenza u-100% wokuhlola okubonwayo kanye ne-AOI kanye nokwenza ukuhlola kukagesi, ukuhlola amandla kagesi aphezulu, ukungakwazi ukusebenza kahle.

ukuhlolwa kokulawula, ukuhlukanisa izingxenye ezincane, ukuhlolwa kokushaqeka okushisayo, ukuhlolwa kwe-solder, ukuhlolwa kokuthembeka, ukuhlolwa kokumelana nokuvikela kanye nokuhlola ukuhlanzeka kwe-ionic.

I-ABIS Isebenza Kanjani Ubunzima Bokukhiqiza I-Aluminium PCB?

Izinto ezingavuthiwe zilawulwa ngokuqinile:Izinga lokuphasa lempahla engenayo lingaphezu kwama-99.9%.Inani lamazinga okunqatshwa kwenqwaba lingaphansi kuka-0.01%.

I-Copper Etching ilawulwa:ucwecwe lwethusi olusetshenziswa kuma-Aluminium PCBs lushubile ngokuqhathaniswa.Uma i-foil yethusi ingaphezu kuka-3oz nokho, ukufakwa kudinga isinxephezelo sobubanzi.Ngemishini enembayo ephezulu engenisiwe evela eJalimane, ububanzi obuncane/isikhala esingasilawula sifinyelela ku-0.01mm.Isinxephezelo sobubanzi bokulandelela sizoklanywa ngokunembile ukuze kugwenywe ububanzi bokulandelela ekubekezeleni ngemva kokubhala.

Ukuphrinta Kwemaski Yekhwalithi Ephezulu:Njengoba sonke sazi, kunobunzima bokuphrinta imaski ye-solder ye-aluminium PCB ngenxa yokuqina kwethusi.Lokhu kungenxa yokuthi uma i-trace copper iminyene kakhulu, khona-ke isithombe esiqoshiwe sizoba nomehluko omkhulu phakathi kwe-trace surface nebhodi lesisekelo kanye nokuphrinta kwemaski ye-solder kuzoba nzima.Sigcizelela ezindinganisweni eziphakeme kakhulu zamafutha e-solder mask kuyo yonke inqubo, kusukela kokukodwa kuya kokuphrinta kwemaski ye-solder izikhathi ezimbili.

Ukwenziwa Kwemishini:Ukuze ugweme ukunciphisa amandla kagesi okubangelwa inqubo yokukhiqiza ngomshini, kuhilela ukubhola ngomshini, ukubumba kanye ne-v-scoring njll. Ngakho-ke, ekwenzeni imikhiqizo enevolumu ephansi, sibeka phambili ukusebenzisa umshini wokugaya ugesi kanye nomsiki wokugaya ochwepheshe.Futhi, sinaka kakhulu ukulungisa amapharamitha wokumba kanye nokuvimbela i-burr ekukhiqizeni.

Isitifiketi

Ukucaciswa kwe-Aluminium Based Copper-clad Laminate

| Into | Hlola a | Ukucaciswa kwe-AL-01-P | I-AL-01-A Ukucaciswa | I-AL-01-L Ukucaciswa | Iyunithi | |

| I-Thermal Conductivity | A | 0.8±20% | 1.3±20% | 2.0±20% | 3.0±20% | W/mK |

| Ukumelana Nokushisa | 0.85 | 0.65 | 0.45 | 0.3 | ℃W | |

| I-Solder Resistance | 288deg.c | 120 | 120 | 120 | 120 | Isiqephu |

| Amandla e-Peel Isimo Esijwayelekile | I-Thermal | 1.2 | 1.2 | 1.2 | 1.2 | N/mm |

| Ukumelana nevolumu Isimo Esijwayelekile | C-96/35/90 E- | 108 | 108 | 108 | 108 | I-MΩ.CM |

| Ukumelana Nobuso Isimo Esijwayelekile | C-96/35/90 E- | 107 | 107 | 107 | 107 | MΩ |

| I-Dielectric Constant | C-96/35/90 | 4.2 | 4.9 | 4.9 | 4.9 | 1MH2 |

| I-Disipation Factor | C-96/35/90 | ≤0.02 | ≤0.02 | ≤0.02 | ≤0.02 | 1MH2 |

| Ukumuncwa Amanzi | 0.1 | 0.1 | 0.1 | 0.1 | % | |

| Ukuhlukaniswa kweVolte | D-48/50+D-0.5/23 | 3 | 3 | 3 | 3 | I-KV/DC |

| Amandla e-Insulation | A | 30 | 30 | 30 | 30 | KV/mm |

| Phakamisa uCamber | A | 0.5 | 0.5 | 0.5 | 0.5 | % |

| Ukuvutha umlilo | UL94 | V-0 | V-0 | V-0 | V-0 | |

| CTi | I-IEC60112 | 600 | 600 | 600 | 600 | V |

| TG | 150 | 130 | 130 | 130 | ℃ | |

| Ubukhulu bomkhiqizo | Isikrini se-actinium siwugqinsi : 1 oz~15 oz, Ibhodi le-aluminium liwugqinsi: |

| Ukucaciswa Komkhiqizo | 1000×1200 500×1200(mm) |

| • Okufakwayo kwemishini yefrikhwensi yezwi,isikhulisamandla esikhiphayo,i-capacitor enxephezelayo, isikhulisi sefrikhwensi yezwi,i-preamplifier, isikhulisi samandla njll. • Imishini yokuphakela amandla: uchungechunge lokulawulwa kwamandla kagesi, imoduli yokushintsha, kanye ne-DC-AC transducer …njll. • Imishini ye-electron yokuxhumana ngocingo iamplifier ephezulu, ucingo lwefiter, thumela ucingo lwetelegram. • I-Office automation:umshayeli wephrinta,i-electronic display substrate enkulu kanye nesigaba sokuphrinta esishisayo A. • I-autocar i-igniter, imoduli yokuphakela amandla kanye nomshini wokushintshashintsha, isilawuli sokuphakela amandla, iba yisistimu kuphela njll. • Isibali.Ibhodi le-CPU, umshayeli wepani elithambile, kanye nedivayisi yokuphakela amandla ... njll. • Inqwaba yesikhunta samandla: ukushintsha ukugeleza komshini, ukudluliswa okuqinile, ibhuloho labahambi njll. • Ukukhanya kwe-LED, izindleko zokushisa namanzi: ukukhanya kwe-LED yamandla amakhulu, udonga lwe-LED njll | |

FAQ

a), Ihora eli-1 elicashuniwe

b), amahora ama-2 wempendulo yesikhalazo

c), 7*24 amahora ukwesekwa lobuchwepheshe

d), 7*24 isevisi ye-oda

e), ukulethwa kwamahora angu-7*24

f), 7*24 ukuqhutshwa kokukhiqiza

Ngokuvamile izinsuku ezingu-2-3 zokwenza isampula.Isikhathi sokuhola sokukhiqiza ngobuningi sizoncika enanini le-oda kanye nesizini ofaka ngayo i-oda.

Ihlolwe phakathi namahora angu-12.Uma umbuzo kanjiniyela kanye nefayela elisebenzayo selihloliwe, sizoqala ukukhiqiza.

ISO9001, ISO14001,UL USA&USA Canada,IFA16949, SGS, RoHS report.

| Amandla okukhiqiza wemikhiqizo edayiswayo eshisayo | |

| I-Double Side/Multilayer PCB Workshop | I-Aluminium PCB Workshop |

| Amandla Obuchwepheshe | Amandla Obuchwepheshe |

| Izinto ezisetshenziswayo: CEM-1, CEM-3, FR-4(High TG), Rogers, TELFON | Izinto ezisetshenziswayo: Isisekelo se-Aluminium, isisekelo sethusi |

| Isendlalelo: Isendlalelo esingu-1 kuye kwezingu-20 | Isendlalelo: Isendlalelo esingu-1 kanye Nezendlalelo ezi-2 |

| Ububanzi/isikhala somugqa omncane: 3mil/3mil(0.075mm/0.075mm) | Ububanzi/isikhala somugqa omncane: 4mil/4mil(0.1mm/0.1mm) |

| Usayizi we-Min.Hole: 0.1mm(imbobo yokubhoboza) | Okuncane.Usayizi wembobo: 12mil(0.3mm) |

| Ubukhulu.Usayizi webhodi: 1200mm* 600mm | Usayizi webhodi eliphezulu: 1200mm* 560mm(47in* 22in) |

| Ugqinsi lwebhodi eliqediwe: 0.2mm-6.0mm | Ugqinsi lwebhodi eliqediwe: 0.3 ~ 5mm |

| Ubukhulu be-foil yethusi: 18um~280um(0.5oz~8oz) | Ubukhulu be-foil yethusi: 35um~210um(1oz~6oz) |

| I-NPTH Hole Ukubekezelela: +/-0.075mm, PTH Ukubekezelela Imbobo: +/-0.05mm | Ukubekezelela isikhundla sembobo: +/-0.05mm |

| Ukubekezelela Kohlaka: +/-0.13mm | Ukubekezelela kohlaka lomzila: +/ 0.15mm;ukubekezelela kohlaka lokubhoboza:+/ 0.1mm |

| Indawo engaphezulu iqediwe: I-HASL engenamthofu, igolide lokucwiliswa (ENIG), isiliva lokucwiliswa, i-OSP, ucwecwe lwegolide, umunwe wegolide, I-Carbon INK. | Ubuso buqediwe: I-HASL yamahhala yokuhola, igolide lokucwiliswa (ENIG), isiliva lokucwiliswa, i-OSP njll |

| Ukubekezelelwa kokulawulwa kokuphazamiseka: +/-10% | Hlala ukubekezelela ukujiya: +/-0.1mm |

| Amandla okukhiqiza: 50,000 sqm/ngenyanga | I-MC PCB Amandla okukhiqiza: 10,000 sqm/ngenyanga |

Izinqubo Zethu Zokuqinisekisa Ikhwalithi njengoba ngezansi:

a), Ukuhlola Okubonwayo

b), I-Flying probe, ithuluzi lokulungisa

c), Ukulawulwa kokuphazamiseka

d), ukutholwa kwekhono le-Solder

e), Isibonakhulu se-Metallogricic Digital

f), i-AOI (Ukuhlola okuzenzakalelayo kokubona)

Yebo, siyajabula ukuhlinzeka ngamasampula emojula ukuze sihlole futhi sihlole ikhwalithi, i-oda lesampula elixubile liyatholakala.Sicela uqaphele ukuthi umthengi kufanele akhokhele izindleko zokuthumela.

Izintengo zethu zingashintsha kuye ngokuhlinzekwa nezinye izici zemakethe.Sizokuthumelela uhlu lwamanani olubuyekeziwe ngemuva kokuthi inkampani yakho ithumele umbuzo kithi.

Sihlinzeka ngempahla ngokwemithetho ebekwe yinkampani esheshayo, ayisekho imali ethe xaxa.

Izinga lokulethwa ngesikhathi lingaphezu kwama-95%

a), ukujika okusheshayo kwamahora angama-24 kwe-PCB eseceleni okukabili

b), amahora angu-48 wezendlalelo ezingu-4-8 sibonelo se-PCB

c), ihora elingu-1 lekhotheshini

d), amahora ama-2 ombuzo kanjiniyela/Impendulo yesikhalazo

e), amahora angama-7-24 okusekelwa kobuchwepheshe/isevisi yoku-oda/ukusebenza kokukhiqiza